The last post on brewing hard cider was on monitoring the fermentation. It was observed that after a week, the gravity was around 1.030 and it looked like it needed a few more days to reach the 1.012 range. Well, unfortunately, I fell sick and had trouble getting out of bed for a few days. By the time I was well enough again to get out of bed, I realized that my cider had over-shot the target and ended up at 1.010 — oh noes!

The last post on brewing hard cider was on monitoring the fermentation. It was observed that after a week, the gravity was around 1.030 and it looked like it needed a few more days to reach the 1.012 range. Well, unfortunately, I fell sick and had trouble getting out of bed for a few days. By the time I was well enough again to get out of bed, I realized that my cider had over-shot the target and ended up at 1.010 — oh noes!

Fortunately, that’s not really a problem. It’s just an opportunity to talk about re-sweetening or back sweetening, as some people like to call it…

Since the cider was at 1.010 and was still bubbling away, it was time to stop the cider from fermenting. Normally, the recommendation for Campden tablets (Sodium- or Potassium-metabisulfite) is to crush them up and use 1 per gallon (~3.75 liters) to “purify” the cider of bacteria and wild yeast. But since the yeast is going full throttle, we need to do 2 things:

- Crush up 1 campden tablet per gallon (3.75 liters) and add to the fermenting cider

- Chill the cider to around 40°F (~5°C) to help fully halt fermentation and cold crash the yeast

TIP: When crushing up the campden tablets, don’t fully pulverize the tablets into a fine powder. Leave some small chunks to sink to the bottom to help kill the yeast living on the bottom of the fermenter. If you only use a fine powder, the majority of the sulfur dioxide will remain in the top half of the fermenter and you’ll have to manually stir up the cider to get even distribution.

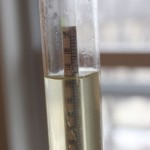

After 24 to 48 hours chilling on my back porch (where it is winter time this time of year), the yeast were pretty much completely dead, the sulfur dioxide cleared from the cider, and the yeast had settled out nicely to the bottom of the carboy. In fact, the cider was a nice translucent color. Not quite clear, but definitely not murky or opaque like sweet cider.

Now it is time to transfer the cider to secondary. This is done partly to get the cider off the dead yeast, but also to prevent re-fermentation. Some of the yeast sitting in the bottom are still alive and if left to sit around long enough will re-start fermentation. To make things more interesting, two carboys were used and 1/2 of the 5 gallons (19 liters) was moved into each carboy. In the bottom of each carboy enough Potassium Sorbate was added to help prevent any remaining yeast from growing and restarting fermentation. Then an auto-siphon was used to transfer into the carboys.

At this point, a 1/2 gallon (1.9 liters) of supermarket apple juice was purchased and added to one of the secondaries. This brought the gravity up to 1.015 and helped give it a slightly darker, fuller color. At 1.015, it becomes a much sweeter cider. It also makes it a bit less alcoholic at ~4% ABV vs. ~5% ABV of the semi-dry cider in the other secondary.

At this point, a 1/2 gallon (1.9 liters) of supermarket apple juice was purchased and added to one of the secondaries. This brought the gravity up to 1.015 and helped give it a slightly darker, fuller color. At 1.015, it becomes a much sweeter cider. It also makes it a bit less alcoholic at ~4% ABV vs. ~5% ABV of the semi-dry cider in the other secondary.

As an aside, if the 1/2 gallon of apple juice had been added to the full 5 gallons of hard cider at 1.010, then the end result would have been around 1.012 or 1.013, which was the original target. That said, I’m curious which of the two ciders my friends will like the most: the semi-dry cider (at 1.010) -or- the semi-sweet cider (at 1.015). I suppose we can always try mixing them at tasting time as well!

As an aside, if the 1/2 gallon of apple juice had been added to the full 5 gallons of hard cider at 1.010, then the end result would have been around 1.012 or 1.013, which was the original target. That said, I’m curious which of the two ciders my friends will like the most: the semi-dry cider (at 1.010) -or- the semi-sweet cider (at 1.015). I suppose we can always try mixing them at tasting time as well!

8 pings

Skip to comment form ↓